The system comprise a line shaft pump and a dry mounted electric motor. The motor is driven with power generated from a dedicated generator set. Normal system voltage is 6,6 kV, other voltages available on request. The pump hydraulic has been specially designed for FW service and pump is designed to minimize caisson diameter.

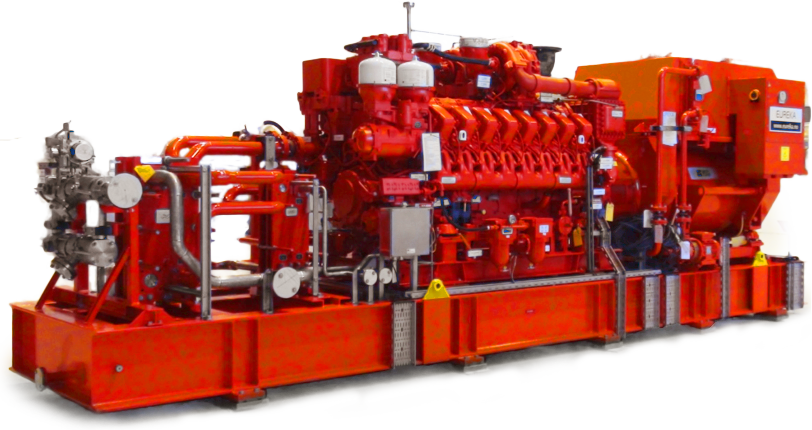

The generator set comprises of a diesel engine mounted on vibration dampers and an alternator mounted on a common baseframe together with auxiliaries.

Heat exchangers for jacket water, turbo after cooler and fuel return are installed on skid.

A Jacket Water heater and circulation pump will keep the diesel engine warm during stand still in order to give an easy start up. Further, an electric lubrication pump will operate prior to test start of the diesel engine and after all normal stop of the same in order to reduce wear and tear for the engine.

The engine start system can be either electric (24VDC), pneumatic or hydraulic and shall have a primary and backup function. The most common solution is a dual electric start system with either pneumatic or hydraulic backup.

A fuel tank will enable the genset to operate for 18/24 hr.

A local control panel (LCP) will monitor and control the whole system. The LCP is complete with necessary instrumentation and control system either as an independent package or fully integrated into the SAS system. An easy-to-use touch panel is mounted in front of the LCP for local operation and monitoring.

The system can operate either in test mode or in fire mode. In test mode a number of alarms will cause the engine to stop. In fire mode only engine over speed and short circuit in generator output will cause shutdown.

The generator is water cooled, also fed from the fire water pump. An electric circulation pump will circulate the water through the generator heat exchanger in order to maintain the operating temperature within limits.

The diesel electric fire water pump system gives a flexible installation as the genset can be installed remote from the pump thus located in safe area while the motor/pump can be located in hazardous area if required. The system is designed to comply to latest edition of NFPA20 with easy access to all maintenance areas. All units will be full load tested prior to delivery at Eureka’s state of the art test centre.