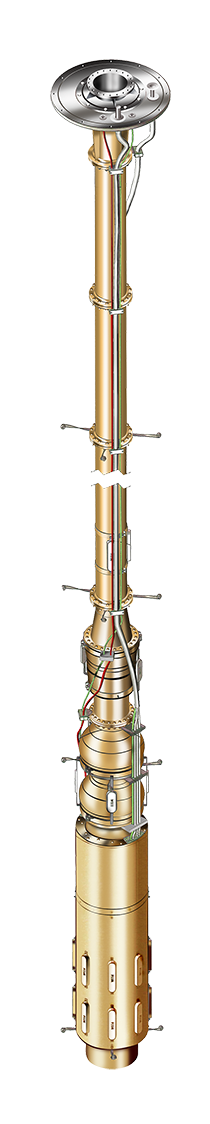

Ballast Pump w/Submerged Electric Motor

Pump and Motor

Pump configurations with submerged electric pumps are designed and manufacture to meet the clients duty requirements and designed according to API610 and any specific client requirements.

Pump configurations with submerged electric pumps are designed and manufacture to meet the clients duty requirements and designed according to API610 and any specific client requirements.

Power is taken from the generator included in this package. Motors are designed to meet the power requirement at any dutyon the pump curve.

The pumps are configured to provide the required discharge pressure at deck level taking into account static lift of seawater from sea level to deck plus any calculated losses in the system.

Seawater is drawn across the suction inlet strainer and into the pump 1st stage suction. Pumps are delivered in a number of stages necessary to meet the requested discharge pressure The liquid is discharged up through the riser column assembly and out of the pump discharge nozzle where it enters the fire water distribution system.

The Eureka submerged electric deep well pump is a heavy duty, vertical turbine, product lubricated pump driven by a submerged electric motor. The pump is designed according to API610 latest edition for continuous duty under all operating conditions. This ensures minimum 30 years total design life for the equipment.

Pump capacity range is between 50 and 10,000 m3/hr. Eureka Pumps pay special attention to optimize pump selection in order to provide the most competitive & reliable technical solution to meet the duty conditions.

Balancing of the resulting forces on the rotor ensures optimum thrust bearing lifetime. The reduced thrust forces on the pump minimize any material fatigue. Motors and pumps are submerged therefore point of excitation is below sea level, the rising column is well modelled and thus negates structural vibrations.

The pump unit comprising bowls, impellers and shaft are coupled to the submerged electric motor. A suction inlet strainer is used to prevent large particles from entering the pump suction eliminating damage to internal components during normal operating conditions.

Pump discharge riser columns are fitted according to the pump required length and section lengths to suit the clients requirements, which deliver the process fluid to the discharge nozzle at deck level. Pump bowls, riser assembly and discharge bend are all designed for the required working pressure. Well proven pump hydraulics are employed with simple, easy to maintain and robust pump construction.

Pump discharge riser columns are fitted according to the pump required length and section lengths to suit the clients requirements, which deliver the process fluid to the discharge nozzle at deck level. Pump bowls, riser assembly and discharge bend are all designed for the required working pressure. Well proven pump hydraulics are employed with simple, easy to maintain and robust pump construction.

It is recommended and good practice to take advantage of the Eureka Pumps non return valve which is fitted after the pump unit discharge bowl and before the riser column section. This feature provides two important functions. Firstly it helps to eliminate water hammer in the discharge pipe work system as it maintains a constant liquid column during periods of idleness and it is also available to permit injection of treated seawater for standby mode conditions, which help prevent potential corrosion of internal components.

In addition an air release/ vacuum breaker valve should be installed into the discharge pipe work on the highest point close by the pump discharge elbow.

Pump and motor wetted materials of construction are according to NORSOK M630/M650 typically and 25% Cr. SDSS is standard with optional 22% Cr. or on request NiAlBr also possible.

The submerged electric motors can be supplied with all voltages between 400v and 11,000v.

The motors are water glycol filled with insulated windings.

A deck mounted header tank supplies the motor with water glycol ensuring a constant overpressure in the motor, preventing any leakage of seawater inside the motor during normal operating conditions.

To prevent marine growth the standard Eureka solution is to install hypochlorite dosing distribution. This is manufactured in compatible materials comprising titanium wetted metal parts and special chemical grade hose.

Sacrificial anodes are assembled to the pump parts such as riser columns, NRV, pump unit and electric motor. These are typically sized to give 10 years life, which is normally the only time the pumps are required to be pulled from service allowing periodical inspection and fitting of replacement wear parts if necessary.

Eureka Pumps can performance test pumps in short execution or full length depending on the client specific requirements. At our Sørumsand assembly plant we have a large testing facility, which has a 60 metres deep test pit. We are also able to deliver NPSH testing according to API610.