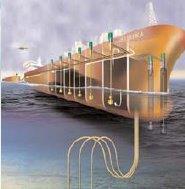

Cargo Lineshaft

Main Features & Benefits

- Pump is designed according to API 610 and suited for offshore duty.

- Proven design for continuous and intermittent duty of minimum 30 years

- Large capacity range from 10 to 10000 m3/h

- Experience with pump length up to 50 meters

- Average availability 99,8 % for our products. Minimum spare parts requirement.

- Optimized HSE values like; high system efficiency, low energy consumption, low noise and safe maintenance.

- All wetted surfaces in corrosion resistant materials, typically SS316 or 22%CrDuplex.

- All critical parts are easily accessible from above deck level in the pump top unit or electro motor.

- Standard rolling element bearing handling the thrust forces. Min. 5 years. Easily accessible from deck level

- Long sleeve bearing lifetime with 5 years between inspections. 10 years or more between replacements of the sleeve bearings. Ceramic sleeve bearings can be supplied for medium with particulate content

- The pump can be disassembled without entering the tank, or in the tank when equipped with dismantling boxes.

- Journal bearing distance is according to API 610. The running speed of the pump is max. 75 % of the critical speed, resulting in low vibration level

- Sleeve bearings have excellent dry running capabilities during start up.

- Standard and well proven dry mounted electric motors with no limitation in power, Zone requirement and voltage.

- VSD drive or two speed electric motors are available.

- Pump is fitted with double mechanical API682 seals with barrier fluid system.

- The pump riser is flexible and is not critical to bulkhead deflection or bending of vessel hull.

- Typically a pump has one intermediate and one bottom support

- High efficiency compared to hydraulic solution. (25% less power requirement)

- High viscosity operation up to 2000 cSt